We provide OEM products according to customer needs. We can design and manufacture products according to customers’ samples or mechanical drawings to meet customers’ specific requirements and standards.

We strictly follow the ISO 9001 quality management system to ensure that the products produced meet high quality standards. We have an experienced quality management team responsible for supervising quality control during the production process and ensuring product quality through various quality inspection methods.

We are able to achieve cost effectiveness. We reduce production costs by improving production efficiency and optimizing production processes, and pass these cost advantages to customers, providing competitive prices.

As a Shanghai-based company, we are able to respond quickly to our customers’ needs. We have complete channels to obtain the required raw materials and parts in a timely manner to ensure the smooth execution of the production plan.

We value every customer and are committed to providing customers with quality pre-sales consultation and after-sales service. We have established long-term and stable cooperative relationships with our customers and won their trust and praise.

We have adopted a series of environmental protection measures, including energy conservation, emission reduction, resource recycling, etc., and are committed to achieving green production.

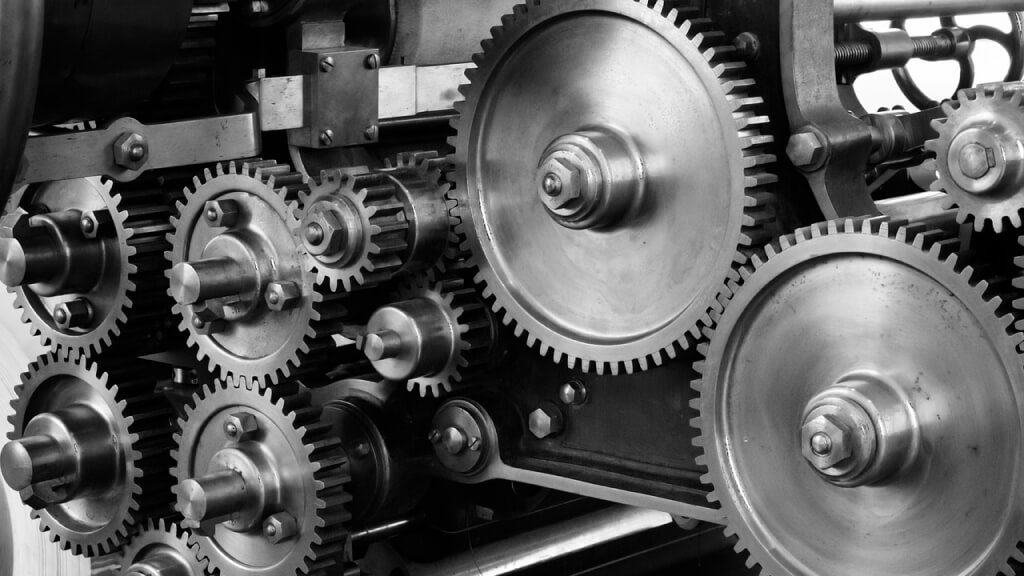

We Started In 1994, And Re-Organized As Shanghai Kinetech Machinery Co., Ltd In 2004. The Kinetech Group Was Established In 2009. The Group Has A Main Factory In Shanghai And 10 Joint Venture Manufacturing Bases In Other Provinces Surrounding Shanghai, With More Than 500 Employees. Focus On Providing High-Quality OE Metal Processing Services, Including Sheet Metal Processing, Lost Foam Casting, Turning, Milling, Stamping And Other Processes.

We are providing a whole package solution of the products in regards to the following materials:

Steel Castings: Use custom metal forging to shape an individual item into a desired form, much as a blacksmith in ancient times forged steel tools. KINETECH can forge unique items to satisfy customer specifications.

Iron Castings: Closed die forgings will produce high volume metal parts without the requirement for extensive machining operations afterwards. KINETECH assists many manufacturers in producing economical parts in quantity using this popular manufacturing technique.

Machined Forging: Create harder bronze and copper parts by using forging. If you require a sturdy yet more water-resistant surface, this manufacturing method offers value. KINETECH will assist you in generating the types of brass and copper forgings your enterprise requires.

Fabrication: The toughest stainless steel parts usually result from the forging process. Use our firm to create durable structural support parts and long-lasting components made from steel.

Machining Process: The forging process assists manufacturers in creating lighter weight hard metal products which may resist extreme environments. BuntyLLC can help you achieve your manufacturing goals in the production of high quality magnesium forgings, from drilling parts to aerospace components.

Assembly: Custom steel forgings enable manufacturers to create very hard, corrosion-resistant steel items. Whether you seek to produce door knobs or automotive parts, when you seek durable steel products and components, BuntyLLC’s forgings can provide the extra-hard tempered surfaces and compacted metal grain properties you prefer.

Other Products: When you require harder aluminum metal parts, aluminum forging may provide a great solution. BuntyLLC will help you create durable yet lightweight metal components produced according to your specifications.